Welding devices from VECTOR WELDING® - technological lead through innovative development and production by our manufacturers and partners

Only the best welders should be used for high-quality welding work. For this reason, we only offer you high-quality and reliable welding inverters with which clean work can be done easily. For any welding process we only offer equipment from VECTOR WELDING®. VECTOR WELDING® welders are convincing due to their technological advantage, as they always have groundbreaking innovations. These welders work extremely efficiently and sustainably.

MIG MAG Welder

Our focus is on MIG MAG Welders, TIG Welders and Plasma cutter, which are used for the most common welding techniques. We also have the best inverters for welding with stick electrodes and pulsed inverter welders. But also welders for fluctuating power supply, which can withstand extreme ambient temperatures, we have in stock for you in addition to inexpensive and highly integrated single-board inverters.

Inverter Welder

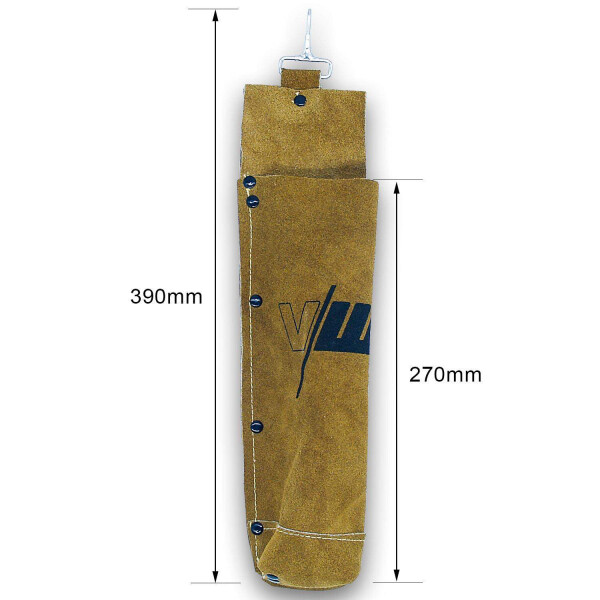

With an inverter welder, you get a compact welding system that is extremely powerful despite its small size, but at the same time has low energy consumption. The combi welder is used especially for mobile applications and is very popular with craftsmen or in workshops. The inverter welders sold by us are equipped with the full VECTOR WELDING® know-how and come exclusively from our own production. We are of course always available to advise you on all products and help you to choose the right equipment for your project. After purchase, you can buy a wide range of welder accessories for your daily welding work from us. In addition to our welders, we offer high-quality Plasma cutter and Welding torches, which also meet the highest demands. We also supply useful items such as cooling devices, wire feeders, welder inert gas or Other welding accessories. The wear parts for all welding techniques can be ordered from us without any problems.

MIG welding

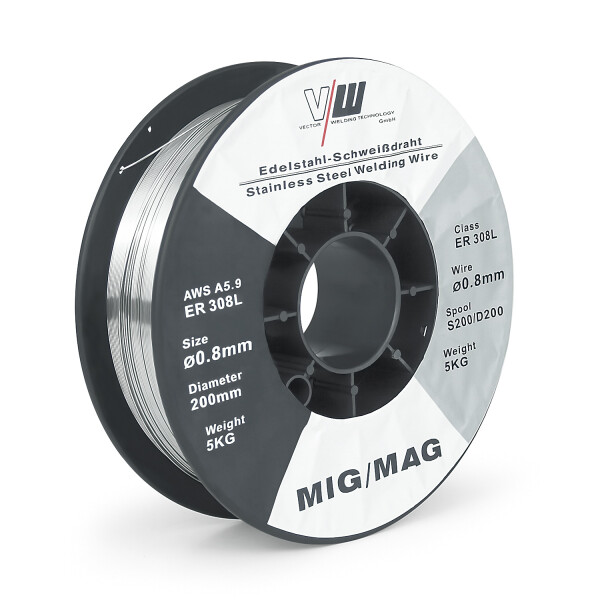

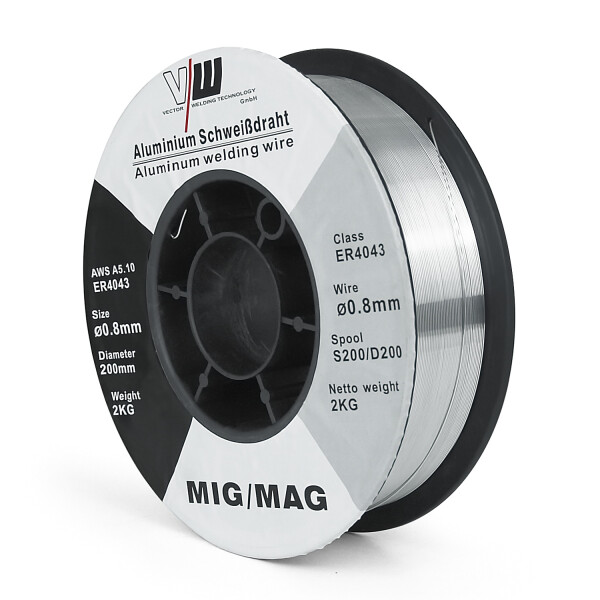

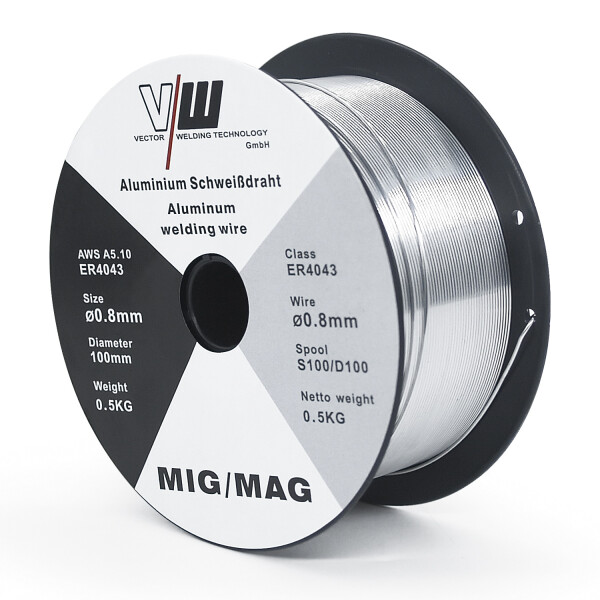

Just like MAG welding, MIG welding is a welding technique and is also called arc welding. A MAG welder is used for welding steel. For work on copper, aluminium or Other materials that are not metal, a MIG welder is used. The work is easily done with our special MIG welders or suitable MAG welders for every imaginable application. These are also known as gas-shielded Welding machines, as shielding gas is supplied during operation. The Welding wire is fed to the welding point by means of a coil, where it melts immediately. The addition of shielding gas prevents oxygen from penetrating the welding spot and the work can be carried out faster and in better quality, as the temperature is much higher. In addition, there is no oxidation of the weld seam as there is no oxygen present. The shielding gas used is usually Aragon, more rarely helium or a mixture of the two. Aragon is cheaper and is therefore preferred. MIG MAG welding is mainly used in mechanical engineering, precision engineering and nuclear technology.

TIG Welder

TIG welding is a fusion welding process and is always used when clean processing is required. This electrode welding machine uses a tungsten electrode to melt the material to be processed. Very fine weld seams are produced, as a supply of shielding gas occurs, which also prevents oxidation of the weld seam in this process. Additional materials such as welding rod must be added manually. A TIG Welder is often used when processing steel, aluminium or stainless steel sheets. The TIG technique is often used in the aviation industry, aerospace, steel construction or the construction of pipelines. On the one hand, this method is very fast, but it is also easy to automate for mass production.

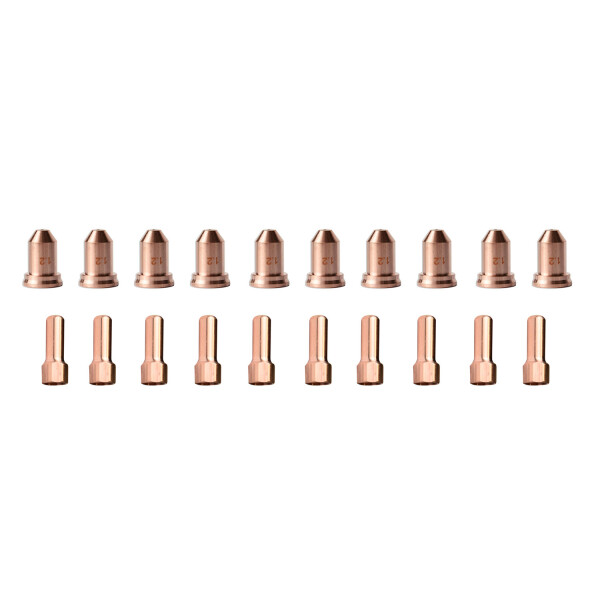

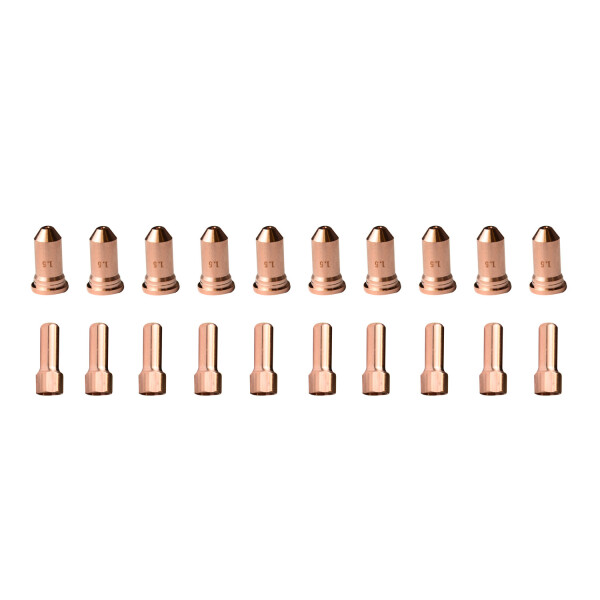

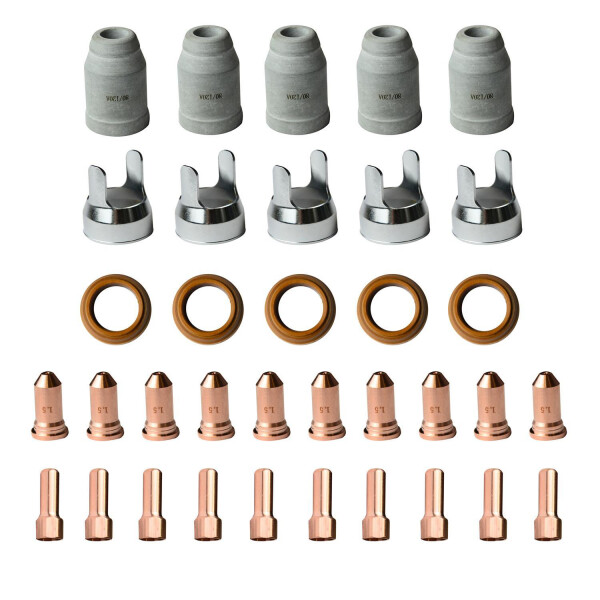

Plasma Cutter

A Plasma cutter is used to cut different metals. This is done with a plasma arc, which is generated by means of an electrically conductive gas. During this process, high voltages are generated between two electrodes, which cause the arc to form. The Plasma cutting device focuses the plasma beam through copper nozzles which must be well insulated, as the plasma beam reaches temperatures of 30,000C. These nozzles are a component with a high wear rate in a Plasma cutting unit. As soon as the metal comes into contact with the arc, it starts to melt. In Plasma Cutter the kerf is created depending on the gas used to remove the molten metal. However, shielding gas is only used if the kerf is to be particularly clean. In most cases compressed air is used. A plasma torch is preferably used to cut metal sheets or make cut-outs.