Schweißgeräte Fachhändler VECTOR WELDING®

Schweißgeräte und Plasmaschneider beim Profi kaufen.

Neugierig auf alle unsere Schweißgeräte?

Klicken Sie hier und sehen Sie das gesamte Sortiment!

Welches Material möchtest du schweißen?

Vector Welding Geräteserien

Die Vector Welding Basic Series ist für Anfänger und den Hobbybereich hervorragend geeignet.

Die besonders attraktiven Preise bieten eine tolle Gelegenheit für den Einstieg in die Welt des Schweißens.

Die Vector Welding Performance Series sind optimal für Heimwerker und Handwerker, die regelmäßig schweißen und das Gerät häufig unter höchster Leistung verwenden.

Hier finden Sie das perfekte Preis-Leistungs-Verhältnis.

Die Vector Welding Industrial Series ist perfekt für Handwerker, die das Gerät täglich im Einsatz haben.

Die besonders robusten Bauteile sind auf dauernde Belastungen ausgelegt und sind damit geeignet für den Mehrschichtbetrieb.

Schweißgerät mit Inverter Technologie

Unsere Schweißgeräte bestechen im Verhältnis zur Leistung durch ihr geringes Gewicht und kompakter Bauweise. Die Inverter Technologie hat den schweren Trafo ersetzt. Inverter Schweißgeräte sind daher sehr belieb bei Arbeiten im Freien und auf Baustellen, aber auch im Werkstatt- und Hobby-Bereich.

Unsere TOP WIG Schweißgeräte

Performance Series

WIG Schweißen und Plasmaschneider als Kombigerät

Industrial Series

Unsere Top MIG MAG Schweißgeräte

MIG MAG - Basic Series

Performance Series

Fülldraht-Schweißen ohne Gas

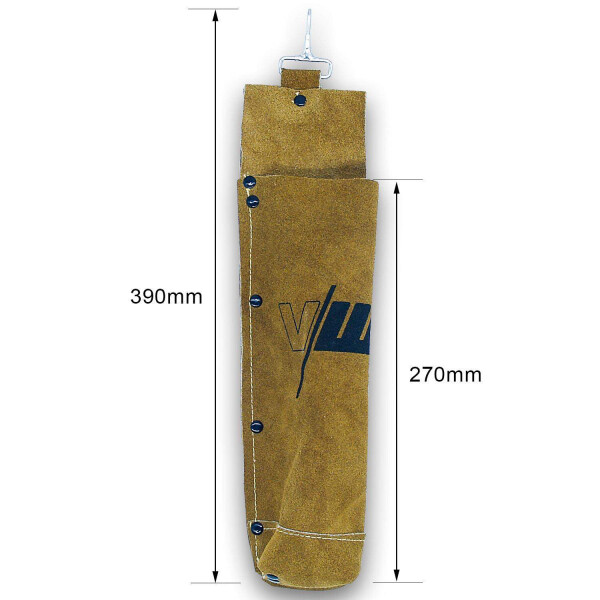

Große Auswahl an Schweißzubehör

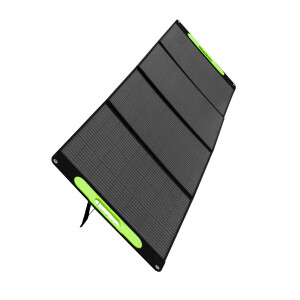

230V ist jetzt überall verfügbar – mit SolarCube

Schweißgeräte von VECTOR WELDING® - technologischer Vorsprung durch innovative Entwicklung und Produktion unserer Hersteller und Partner

Für hochwertige Schweißarbeiten sollten nur die besten Schweißgeräte zum Einsatz kommen. Aus diesem Grund bieten wir Ihnen ausschließlich qualitative und zuverlässige Schweißinverter an, mit denen ein sauberes Arbeiten leicht von der Hand geht. Für jegliche Schweißverfahren bieten wir nur Geräte von VECTOR WELDING® an. VECTOR WELDING® Schweißgeräte überzeugen durch Ihrem technologischen Vorsprung. da diese stets über wegweisende Neuerungen verfügen. Unsere Schweißgeräte arbeiten äußerst effizient und nachhaltig.

MIG MAG Schweißgeräte

Unsere Schwerpunkte sind MIG MAG Schweißgeräte, WIG Schweißgeräte und CUT Plasmaschneider, welche für die häufigsten Schweißtechniken eingesetzt werden. Des Weiteren verfügen wir über die besten Inverter für Schweißarbeiten mit Stabelektroden sowie gepulste Inverter Schweißgeräte. Aber auch Schweißgeräte für schwankende Spannungsversorgung, welche extremen Umgebungstemperaturen standhalten, haben wir neben den günstigen und hochintegrierten Einplatinen-Invertern für Sie vorrätig.

Inverter Schweißgerät

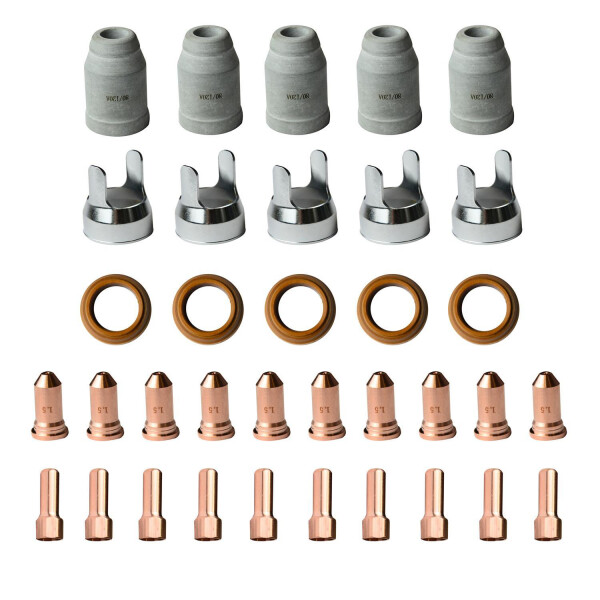

Mit einem Inverter Schweißgerät bekommen Sie eine kompakte Schweißanlage, die trotz ihrer geringen Größe extrem Leistungsstark ist, gleichzeitig aber einen geringen Energieverbrauch aufweist. Vor allem bei mobilen Einsätzen kommt das Kombi Schweißgerät zum Einsatz und ist sehr beliebt bei handwerklichen Betrieben oder in Werkstätten. Die von uns vertriebenen Inverter Schweißgeräte sind mit dem vollen Vector Welding Know-how ausgestattet und stammen ausschließlich aus eigener Produktion. Bei der Beratung rund um alle Produkte stehen wir Ihnen natürlich jederzeit zur Seite und helfen bei der Wahl des richtigen Gerätes für Ihre Vorhaben. Nach dem Kauf können Sie bei uns vielfältiges Schweißgeräte Zubehör für die täglichen Schweißarbeiten kaufen. Neben unseren Schweißgeräten bieten wir hochwertige Plasmaschneider und Schweißbrenner an, die ebenfalls den höchsten Ansprüchen gerecht werden. Auch hierzu liefern wir nützliche Dinge wie Kühlgeräte, Drahtvorschubgeräte, Schweißgerät Schutzgas oder anderes Schweißzubehör. Die Verschleißteile für sämtliche Schweißtechniken können problemlos bei uns bestellt werden.

Vorteile der Inverter Schweißgeräte:

- kleines Volumen

- geringes Gewicht

- materialsparend

- leicht zu transportieren und zu bewegen.

- hoher Wirkungsgrad und Energieeinsparung, der Wirkungsgrad kann 80% ~ 90% erreichen, was mehr als 1/3 der Elektrizität im Vergleich zu herkömmlichen Schweißmaschinen einspart.

- gute dynamische Eigenschaften

- leichte Lichtbogenzündung

- stabiler Lichtbogen

- schöne Schweißnahtbildung

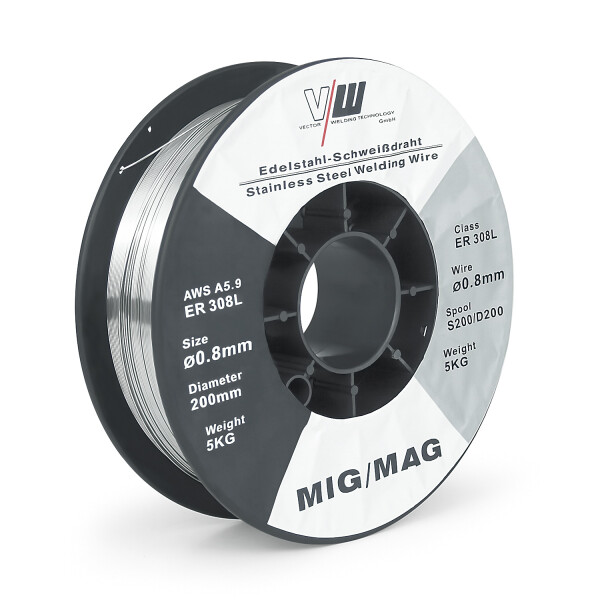

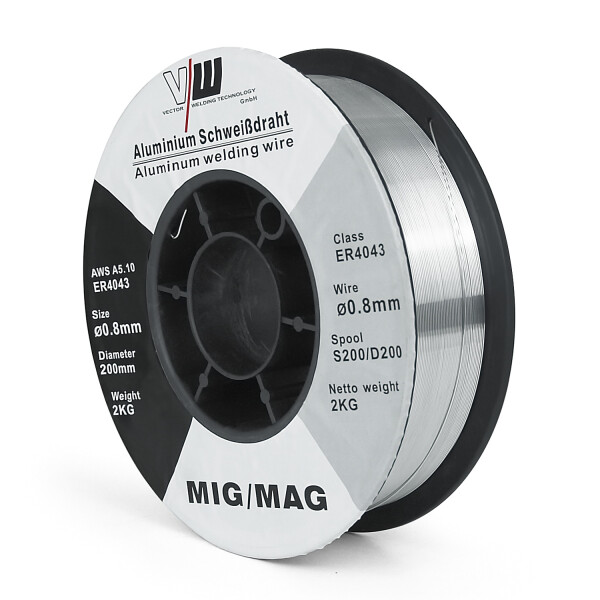

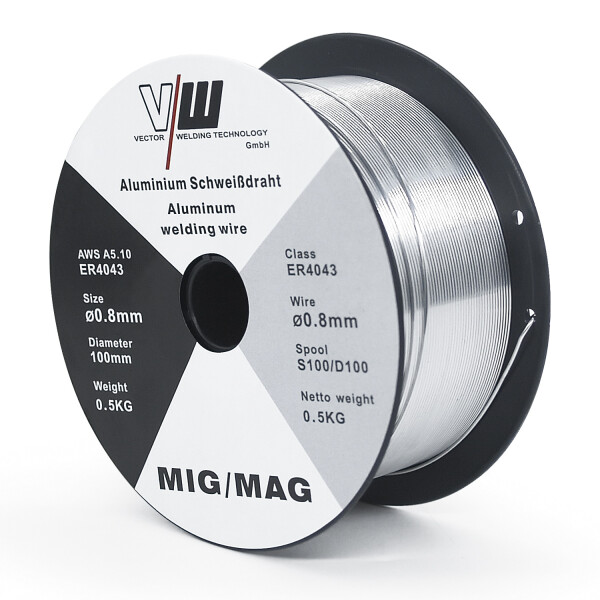

MIG Schweißen

Das MIG Schweißen ist genau wie das MAG Schweißen eine Schweißtechnik und wird auch Lichtbogenschweißen genannt. Für das Schweißen von Stahl wird ein MAG Schweißgerät verwendet. Bei Arbeiten an Kupfer, Aluminium oder anderen Materialien die nicht aus Metall bestehen, kommt ein MIG Schweißgerät zum Einsatz. Die Arbeit geht leicht von der Hand mit unseren speziellen MIG Schweißgeräten oder passenden MAG Schweißgeräten für jeden erdenklichen Einsatz. Diese sind auch als Schutzgasschweißgerät bekannt, da währen dem Betrieb Schutzgas zugeführt wird. An die Schweißstelle wird mittels einer Spule der Schweißdraht geführt, wo er unmittelbar schmilzt. Das Hinzufügen von Schutzgas verhindert das Eindringen von Sauerstoff auf den Schweißpunkt und die Arbeiten können schneller und in besserer Qualität ausgeführt werden, da eine deutlich höhere Temperatur herrscht. Außerdem kommt es zu keiner Oxidation der Schweißnaht, da kein Sauerstoff vorhanden ist. Das verwendete Schutzgas besteht meistens aus Aragon, seltener aus Helium oder einem Gemisch der Beiden. Aragon ist günstiger und wird somit bevorzugt. Das MIG MAG Schweißen kommt vor allem im Maschinenbau, der Feinwerktechnik und Kerntechnik zum Einsatz.

WIG Schweißgeräte

Das WIG Schweißen, im englischen TIG Schweißen, ist ein Schmelzschweißverfahren und wird immer dann angewendet, wenn es auf eine saubere Verarbeitung ankommt. Dieses Elektrodenschweißgerät lässt das zu bearbeitende Material mit Hilfe einer Wolfram-Elektrode aufschmelzen. Es entstehen sehr feine Schweißnähte, da es zu einer Zuführung von Schutzgas kommt, die auch bei diesem Verfahren eine Oxidation der Schweißnaht verhindert. Zusatzmaterialien wie Schweißdraht müssen manuell hinzugegeben werden. Ein WIG Schweißgerät kommt häufig bei der Verarbeitung von Blechen aus Stahl, Aluminium oder Edelstahl zum Einsatz. In der Luftfahrtbranche, der Raumfahrt, Stahlbau oder der Konstruktion von Rohrleitungen wird die WIG Technik oft verwendet. Zum einen ist dieses Verfahren sehr schnell, aber diese Methode lässt sich auch gut für die Massenproduktion automatisieren.

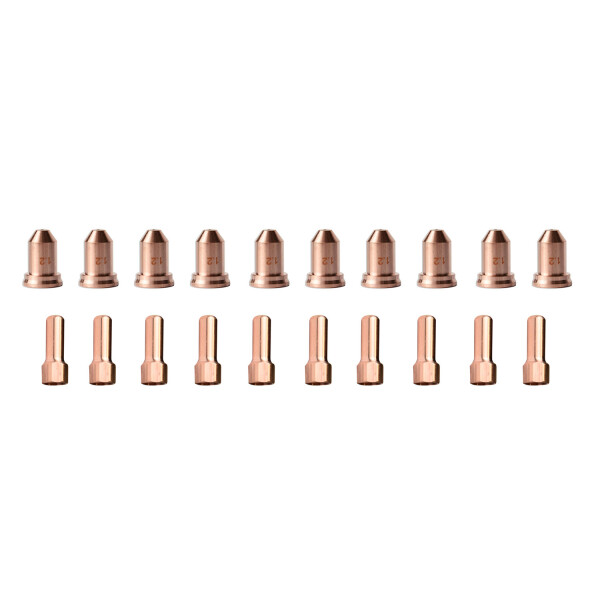

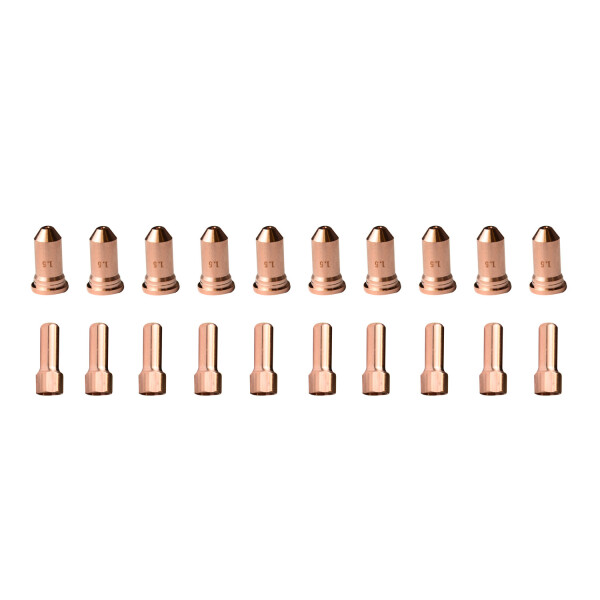

Plasmaschneider

Mit einem Plasmaschneider werden unterschiedliche Metalle zugeschnitten. Das geschieht mit einem Plasma Lichtbogen, der mit Hilfe von einem elektrisch leitfähigen Gas erzeugt wird. Bei diesem Vorgang kommt es zu hohen Spannungen zwischen zwei Elektroden, die den Lichtbogen entstehen lassen. Das Plasmaschneidegerät bündelt den Plasmastrahl durch Kupferdüsen die gut isoliert sein müssen, da der Plasmastrahl Temperaturen von 30.000C erreicht. Diese Düsen sind bei einer Plasmaschneideanlage ein Bauteil mit hoher Verschleißrate. Sobald das Metall mit dem Lichtbogen in Berührung kommt, fängt es an zu schmelzen. Beim Plasmaschneiden entsteht die Schnittfuge abhängig vom verwendeten Gas, mit dem das geschmolzene Metall entfernt wird. Schutzgas wird jedoch nur verwendet, wenn die Fuge besonders sauber werden soll. In den meisten Fällen wird Druckluft verwendet. Mit einem Plasmabrenner werden vorzugsweise Metallbleche zugeschnitten oder Ausschnitte angefertigt.

Schweißgeräte & Zubehör aus Köln

Mit Vector Welding haben Sie immer einen Experten an Ihrer Seite, der Sie tatkräftig bei allen Projekten unterstützen kann. Vertrauen Sie auf Qualität und hochwertige Geräte und profitieren Sie von den zahlreichen Vorteilen.

Ganz gleich, ob Sie ein WIG Schweißgerät , Plasmaschneider oder Schweißzubehör kaufen möchten, unsere fortschrittlichen Produkte werden Ihren Ansprüchen garantiert gerecht.

Vector Welding Schweißgeräte

Seit 2013 sind wir Schweißfachhändler von VECTOR WELDING Schweißgeräten & Plasmaschneidern. Im Jahr 2016 wurde die Firma in VECTOR WELDING umfirmiert. Unser Partner und Gesellschafter beliefert uns aus eigener Produktionsstätte von über 5.000 m² und 60 Mitarbeitern weltweit, wovon 4 Ingenieure für Forschung und Entwicklung im Schweiß-& Schneidbereich tätig sind.

Wir sind spezialisiert auf tragbare Schweißgeräte für Handwerk, Werkstätten und Privatpersonen. Mit unserem Service erhalten Sie alles aus einer Hand. Die zusätzliche Zubehörgarantie gewährleistet auch in der Zukunft sorgenfreies und nachhaltiges Schweißen und Schneiden.

Beratung, Verkauf, Reparaturservice, Ersatzteil- & Zubehörlager, sowie weltweiter Versand — Probeschweißen vor Ort nach Terminvereinbarung möglich